Case BMS

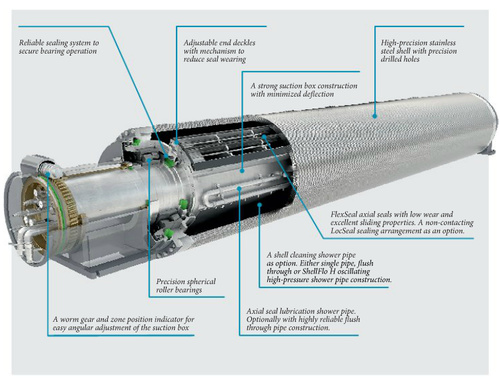

World's leading paper production solutions provider Valmet created a new approach in cooperation with Ramentor for assessing the reliability of their rolls. The solution created during the project allows defining what kind of availability values different roll configurations can achieve and this way ensures more effective conversations with the customers.

The basis of the approach was created with ELMAS software and it was used to analyze the reliability of different suction roll configurations. The project also provided an effective base structure to be used with other reliability analyses. The project personnel from Valmet had a clear view on the project outcome:

- ELMAS analysis gives formal approach with numerical results to compare between various structural and maintenance options. It suits very well for many reliability evaluations of paper machine components, structures and eventually the whole machine.

The approach can be used to show how different available roll options can be used to manage the life-cycle costs (LCC) coming from roll usage and maintenance, and how these options affect the overall availability of the paper machine.

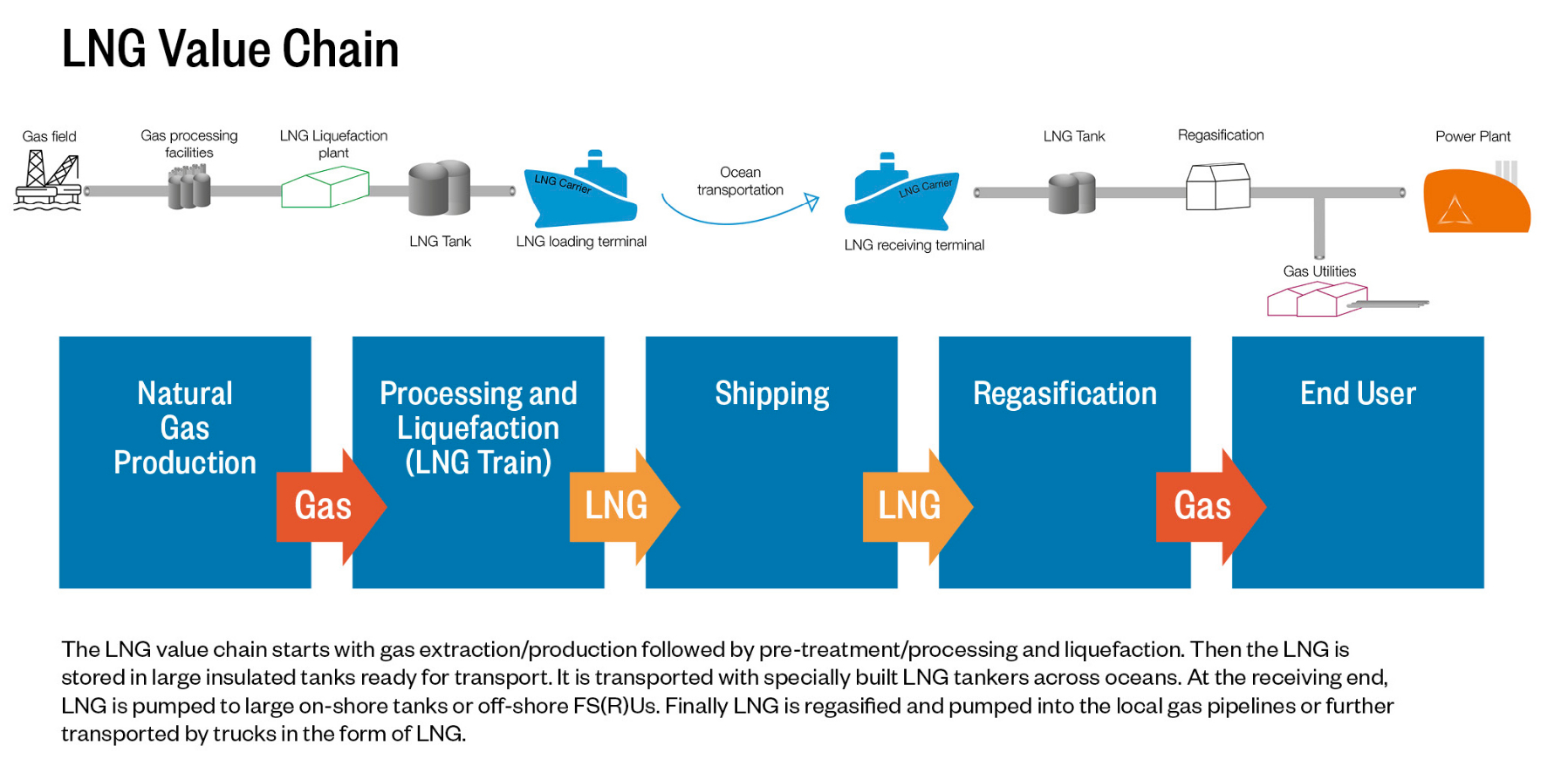

Wärtsilä, a global energy solutions provider, is the supplier of the new liquefied natural gas (LNG) import terminal in Tornio, Finland. This terminal will be the largest such facility in the entire Nordic region. Wärtsilä has an exclusive ten year contract to provide all the service and maintenance required.

ELMAS Design for Maintainability analysis was performed for the regasification process. The goal was to avoid unplanned stops of the terminal in a scenario where at least one of the regasification units is needed to ensure constant operation. The analysis identified the most critical chains of events causing the unavailability. Based on the results Wärtsilä was able to optimize the repair and maintenance strategies. The maintenance organization now understands the resources required to the long-term maintenance contract.

The results will be utilized for the training of Wärtsilä experts to better understand the dependability and overall lifecycle management of complex systems. Next the analysis is continued to cover other subsystems and also different production scenarios where multiple regasification units are required. At early design stage the approach can be used to improve the current design and to find out any possible design flaws affecting the system availability.

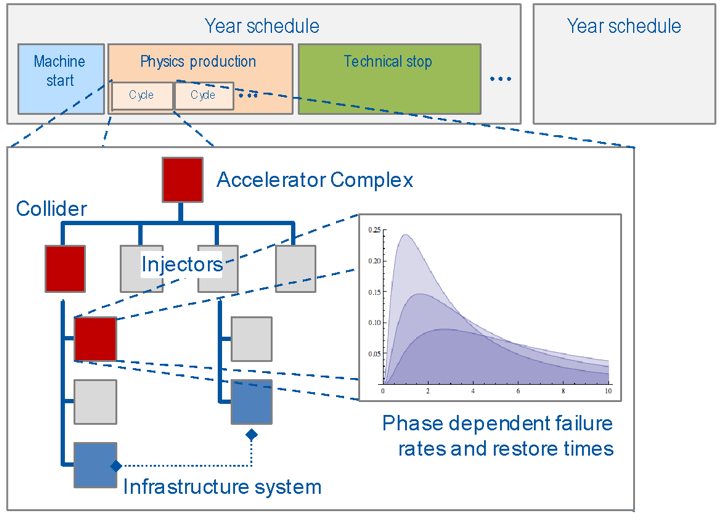

The idea is to combine experience from RAMS experts (TUT, Ramentor) with CERN knowledge on accelerators. ELMAS (Event Logic Modeling and Analysis Sofware) is used to model the collider systems and to simulate the particle acceleration process. The analyses are used to find possibilities to improve the LHC and to assess the cost vs dependability requirements for the FCC.

The FCC study launched also a training programme on Accelerator Reliability and Availability (ARA) engineering at CERN. The goal is to build a common foundation in the field of reliability engineering for particle accelerators and to create an active network of accelerator engineers who can assess and address reliability topics. Ramentor provides the training together with University of Stuttgart and Tampere University of Technology.

Read more how the same tools can be applied also elsewhere:

Can a future circular collider may make you feel cosy at home?

Read more about the training programme from:

Exploiting the full potential of the LHC and designing sustainable future accelerator infrastructure

Read more about CERN-Ramentor R&D agreement:

A new tool to evaluate complex tech systems’ efficiency

Read more from FCC study page:

Reliability and availability are key quality attributes

Read more from publications:

Modeling Future Hadron Colliders’ Availability for Physics

Availability modeling approach for future circular colliders based on the LHC operation experience

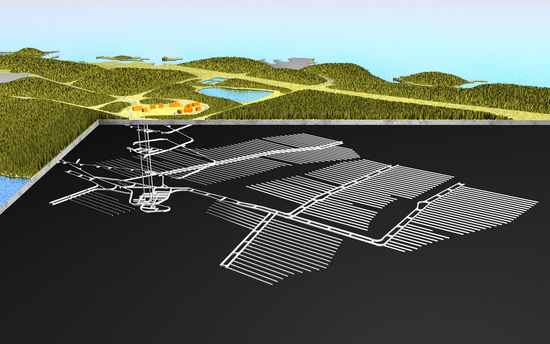

Posiva accounced 12 February 2015 that the Radiation and Nuclear Safety Authority of Finland (STUK) issued to the Finnish Ministry of Employment and the Economy its statement on the safety of Posiva's facility for the encapsulation and final disposal of spent nuclear fuel. STUK concludes in its statement that the criteria set forth in the Nuclear Energy Act are fulfilled and the final disposal facility can be built to be safe. According to STUK, both STUK's own experts and other Finnish and international experts were used for the review of the construction licence application.

Read Posiva's announcement in its entirely: Posiva's announcement

Since 2010 Ramentor's ELMAS (Event Logic Modeling and Analysis Software) has been the method for auditing technical plans and risk analyses. Based on STUK's statement the project can now be continued with detailed engineering.

Data Centers – Main concern on reliability, availability and risk management

"In Finland there are currently large ongoing investments on targets that differ from traditional industrial projects. The amount of data centers required by IT and cloud services is increasing all the time and they are built e.g. into properties of closed paper mills. Execution phase is largely emphasized by life-cycle effectiviness, infrastructure availability and information security, without forgetting energy efficiency."

Promaint article about the project (available only in Finnish): Asiakasprojekti: Konesalit

Dynamic simulation – Results from paper mill sheeting plant

"The production process of the sheeting plant is a very complex entity. By improving its operation it's also possible to improve the overall productivity of the whole mill. With the help of dynamic simulation the bottleneck points of the production were located and the development actions were directed to the right targets."

Promaint article about the project (available only in Finnish): Asiakasprojekti: Efora

Dependability analysis is an effective method for operations development

"Finnish Konecranes is one of the leading global providers of lifting equipment solutions and maintenance services. The company has been already years the technological pioneer of lifting industry. In the future the company strives to strengthen its position on the global markets. One solution for this is the development of preventive maintenance with the help of e.g. dependability and safety related RAMS analyses."

Promaint article about the project (available only in Finnish): Asiakasprojekti: Konecranes

Availability risk recognition brought savings and renewed operation procedures

"With the help of process line dependability analysis it is possible to recognize the critical subsystems and to essentially improve the dependability. When process bottleneck points have been recognized, the renewing of operation procedures can produce cost savings of up to millions of euros achieved by decreased production losses."

Promaint article about the project (available only in Finnish): Asiakasprojekti: Nokian Renkaat

Optimizing maintenance of pulp mill startup with dynamic simulation model

"The pulp mill of Metsä-Botnia Rauma has taken into use in its post stoppage startups a dynamic dependability simulation model, that calculates an optimal startup curve based on the tank level situations."

Automaation tehdaspalvelu article about the project (available only in Finnish): Asiakasprojekti: Botnia Mill Service