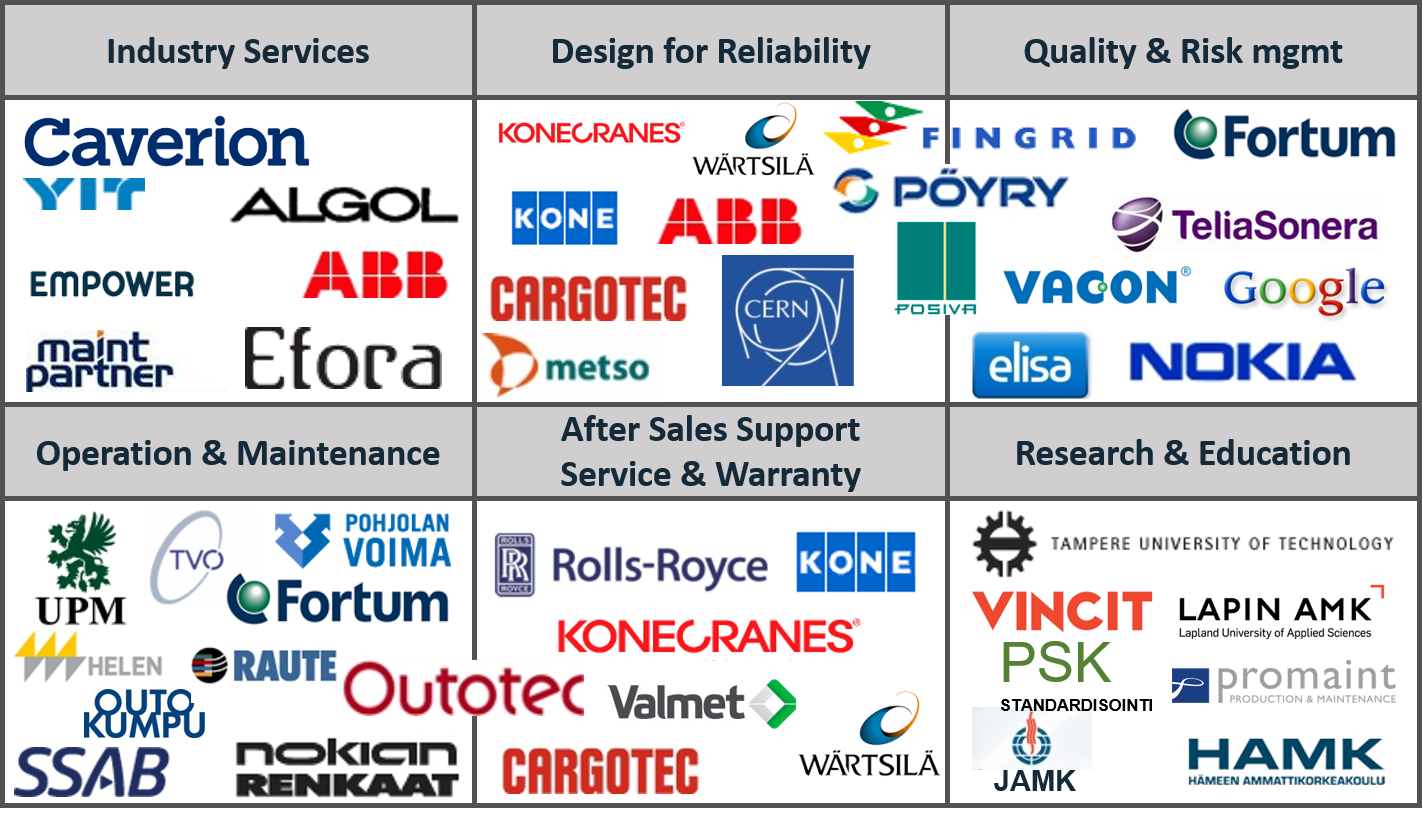

Wärtsilä: Designing availability in research and product development projects of Fuel Cell and Diesel motors: http://www.wartsila.com (Read more: Case Wärtsilä)

Nokian Renkaat: Dependability analyses for process lines, development of OEE management and enhancing the usability of the CMMS: http://www.nokianrenkaat.com

Posiva: Risk assessment and management utilizing ELMAS. Risk analyses based on design review process: http://www.posiva.fi/en

Pöyry: Demanding dependability and risk analyses for various industries. ELMAS is also chosen as the main method in risk evaluations for construction projects: http://www.poyry.com/

Caverion (former YIT Industry Ltd): i.a. development of maintenance outsourcing services, evaluation of process efficiency, dynamic simulation models and criticality analyses: http://www.caverion.com

Efora: Risk analyses, dynamic simulation models and developing maintenance outsourcing: http://www.efora.fi

CERN: ELMAS is used for modelling the collider systems and simulating the particle acceleration process. The analyses aim to find the possibilities to improve the current particle collider system. Read more from FCC study page: Reliability and availability are key quality attributes

Helen: Identifying and analyzing technical risks of district cooling and heating plants through ELMAS dependability analyses: http://www.helen.fi

Raute: Analyzing dependability risks of veneer production and improving maintenance data collection to support the development of process devices and management of LCC: http://www.raute.fi

Fortum: Sustaining and developing safety, availability and performance factors. RCM analyses in Loviisa nuclear plant: http://www.fortum.fi

Rolls-Royce: Design for reliability and development of predictability of service need for propulsion equipment: http://www.rolls-royce.com

Fingrid: Reliability analyses of substations and transmission lines in Finnish utility grid: http://www.fingrid.fi

Pohjolan Voima: Dependability analyses of power plants, identification of critical devices and creating an analytical approach for process dependability development: http://www.pohjolanvoima.fi

Algol Technics: Life-cycle concepts for material handling solutions. Optimizing overall costs of material handling functions by considering maintenance costs, investments and production loss during the whole life-cycle: http://www.algol.fi

Elisa: Developing availability and reliability processes of telecommunication networks: http://www.elisa.com/en

Cargotec: Systematic reliability design of various products and optimizing their maintenance actions: http://www.cargotec.com

Outokumpu: Reliability model and an extensive availability analysis of a processing line in Tornio factory: http://www.outokumpu.com

Ruukki Production: Development of dependability and maintenance, and optimizing reliability and maintenance costs of the critical elements of a manufacturing process: http://www.ruukki.com

Empower: Developing maintenance outsourcing services and analyzing availability of telecommunication networks: http://www.empower.fi

Konecranes: Reliability modeling and service development of cranes and machine tools, and enhancing communication between CMMS and dependability calculations: http://www.konecranes.com

United Paper Mills: OEE calculations, equipment failure analyses and scheduled maintenance program development in several mills. The main goal is to use new methods and tools for enabling dependability-based maintenance strategy (e.g. bottleneck analyses and investment plan): http://www.upm-kymmene.com

ABB Service and ABB Marine: These global ABB business units create projects in various application areas, such as product design and maintenance services: http://www.abb.com

Nokia Technology Platforms: Reliability engineering, requirements management and testing. Also as a tool for product design to perform reliability-based root cause, cause-consequence, failt tree and cause-effect analyses: http://www.nokia.com

Kone R&D and Service units: Reliability engineering and service development, field data collection, focusing operations and giving feedback to desing sector: http://www.kone.com

TeliaSonera Networks: Developing dependability of telecommunication services by applying modeling and simulation: http://www.teliasonera.com

StoraEnso: Optimizing stock levels in Finland and e.g. criticality analysis and maintenance programme optimization of a grinding line: http://www.storaenso.com

Metso Automation: FTA/FMEA modeling, effective problem solving and as a tool in R&D projects helping cooperation between different teams: http://www.metso.com

Vapo Production: Modeling and analyzing the dependability and maintenance of a process line: http://www.vapo.com

Hämeenlinna University of Applied Sciences and AutoMaint: Basic education of maintenance technology and corporate services, optimizing industrial process operations: http://www.hamk.fi

Lapin AMK: Basic education of maintenance and dependability technology in degree programmes of mechanical and production technology together with using ELMAS software in Bachelor´s theses: http://www.lapinamk.fi

Jyväskylä University of Applied Sciences: Basic education and commercial training for maintenance and e.g. RCM-analysis: http://www.jamk.fi

Tampere University of Technology: World-class academic research, basic education and training, consulting and application services for technology companies using RAMS Products: http://www.tut.fi